CECLE Machine

NJP-260 Automatic capsule filling machine Liquid/Oil capsule filler

NJP-260 Automatic capsule filling machine Liquid/Oil capsule filler

Couldn't load pickup availability

Automatic Liquid/Oil capsule filling machine

The maximum production capacity of this machine can reach 260 capsules per minute. Standard and serial production: the interchangeability of manufacturing parts can reach above 99%; each spare part has its own regular code; while changing the mould, all the parts are fixed by the location hole with high precise; it’s very efficient to change the moulds, easy to operate and clean the machine.

|

Model |

NJP-260 |

|

Machine Weight |

900KG |

|

Overall Dimension |

1020*860*1970mm |

|

Motor Power |

5.75KW |

|

Power Supply |

3 phase, four-wire AC 380V 50Hz |

|

Max. Capacity |

260pcs/min |

|

Capsule Size |

00#-5#, secure capsule A-E |

|

Good Filling Rate |

≥99.5% |

|

Noise Index |

≤75dBA |

|

Precision |

Liquid more than 300mg≤±3% |

|

Compressed Air |

0.06m3/min 0.3MPa |

|

Source of Water |

Water-ring vacuum pump matching with water tank to recycle the water, or using external water source. |

|

Vacuum Degree |

-0.02 ~ -0.06 MPa |

|

Water Flowing Rate |

250L/h |

|

Inner Diameter of Inlet Tube |

20mm |

|

Inner Diameter of Outlet Tube |

27mm |

|

Working Temperature |

21℃±3℃ |

|

Plant Height |

Human feeding ≥2.6m, Vacuum feeding ≥2.8m |

|

Relative Humidity |

40-55% |

|

Air Displacement |

300m3/h |

|

Control System |

Stepless frequency converter, PLC control |

|

Material |

All the parts directly contacting with capsule and liquid adopt high quality of 304 and 316L stainless steel. |

- Improve the driving cams of all stations, from original outer cam pulled by spring to inner groove cam made of high-quality special material. This change, eliminating the disadvantages of easy fatigue and short service life for spring pulling method, makes the machine more wearable and stable.

- In consideration of the medicine dust easy to enter the machine mould after long-time running, causing the mould rotary plate to be disassembled for cleaning, the innovation design of seal ring preventing dust from outside is developed and applied to this machine, which completely ensures the sealing in running process and eliminates the shortcoming of tedious maintenance.

- This machine adds the inching control system, convenient for the human-oriented operation in manufacturing and cleaning process.

- If lack of capsule, the liquid feeding will stop automatically.

ConfigurationList

|

Description |

Specification/Model No. |

Brand |

Qty/Unit |

Remark |

|

Exactitude intermission graduator |

Ru83DS-10-150-2R-S2-V-SSS |

Shandong |

1set |

|

|

Main motor |

2HP-1500W |

GPG |

1set |

|

|

Vacuum pump |

SZ-1.5 |

JH |

1set |

|

|

Dust collector |

2.2KW |

Zhejiang |

1set |

|

|

HMI |

TK6070Hi |

WEINVIEW |

1set |

|

|

PLC |

DVP14E |

Delta |

1set |

|

|

Frequency converter |

VFD015B21A |

Delta |

1set |

|

|

Optical axis |

DKNΦ10-20 |

Japan |

1set |

|

|

Linear Bearing |

SDE20Y |

Japan |

8pcs |

|

|

Linear Bearing |

SDE10Y |

Japan |

20pcs |

|

|

Linear Bearing |

SDE12Y |

Japan |

20pcs |

|

|

Needle bearing |

IKDCF12 |

Japan |

5pcs |

|

|

Thermal relay |

NR2-25 |

CHNT |

3pcs |

|

|

AC contactor |

CJX2-25 |

CHNT |

1pc |

|

|

AC contactor |

CJX2-12 |

CHNT |

3pcs |

|

|

Breaker |

DZ47-60-C32 |

CHNT |

1pc |

|

|

Breaker |

DZ47-60-C15 |

CHNT |

1pc |

|

|

Breaker |

DZ47-60-C10 |

CHNT |

1pc |

|

|

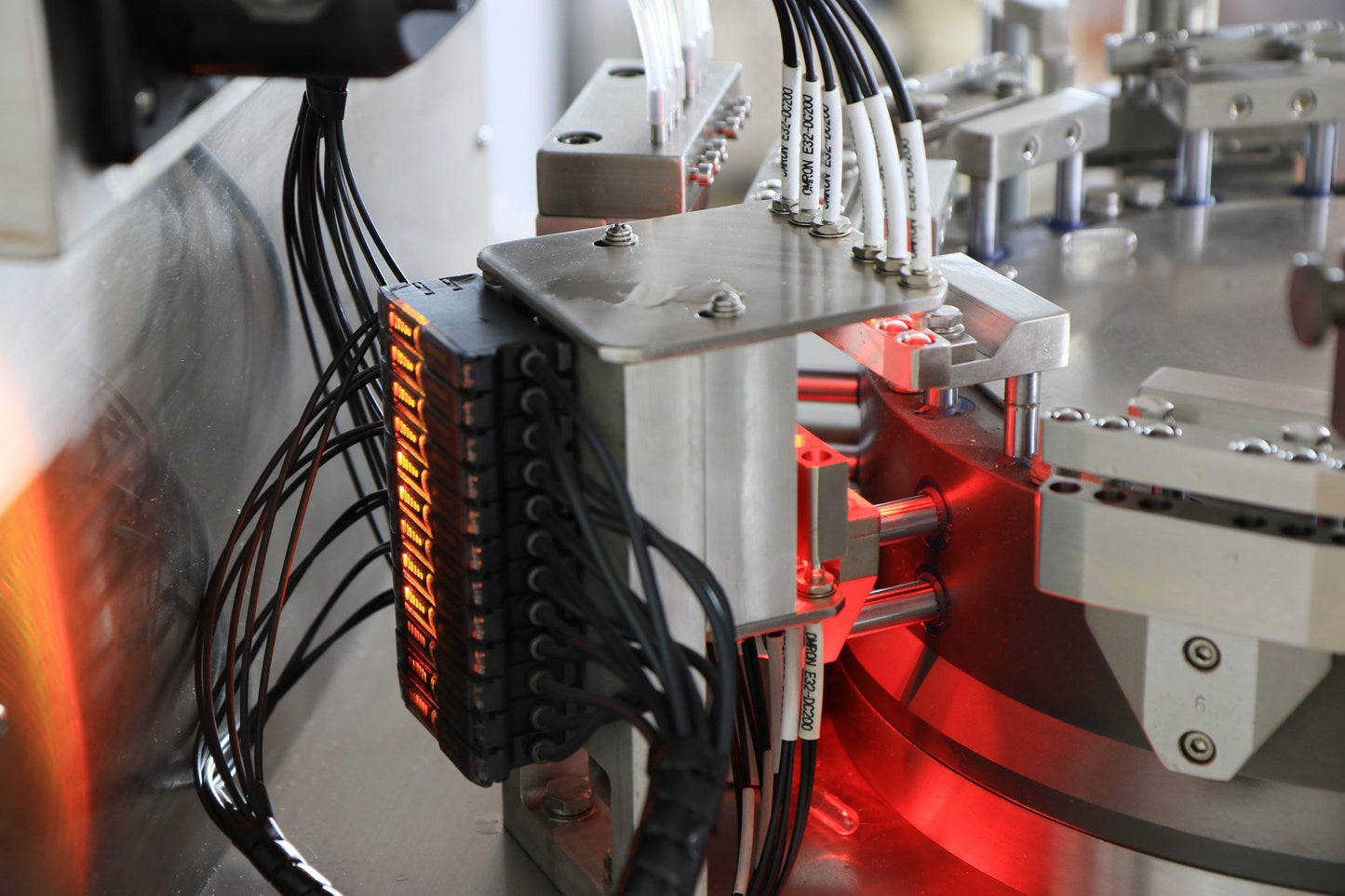

Optical fiber |

E3X-NA11 |

OMRON

|

12pcs |

Share