CECLE Machine

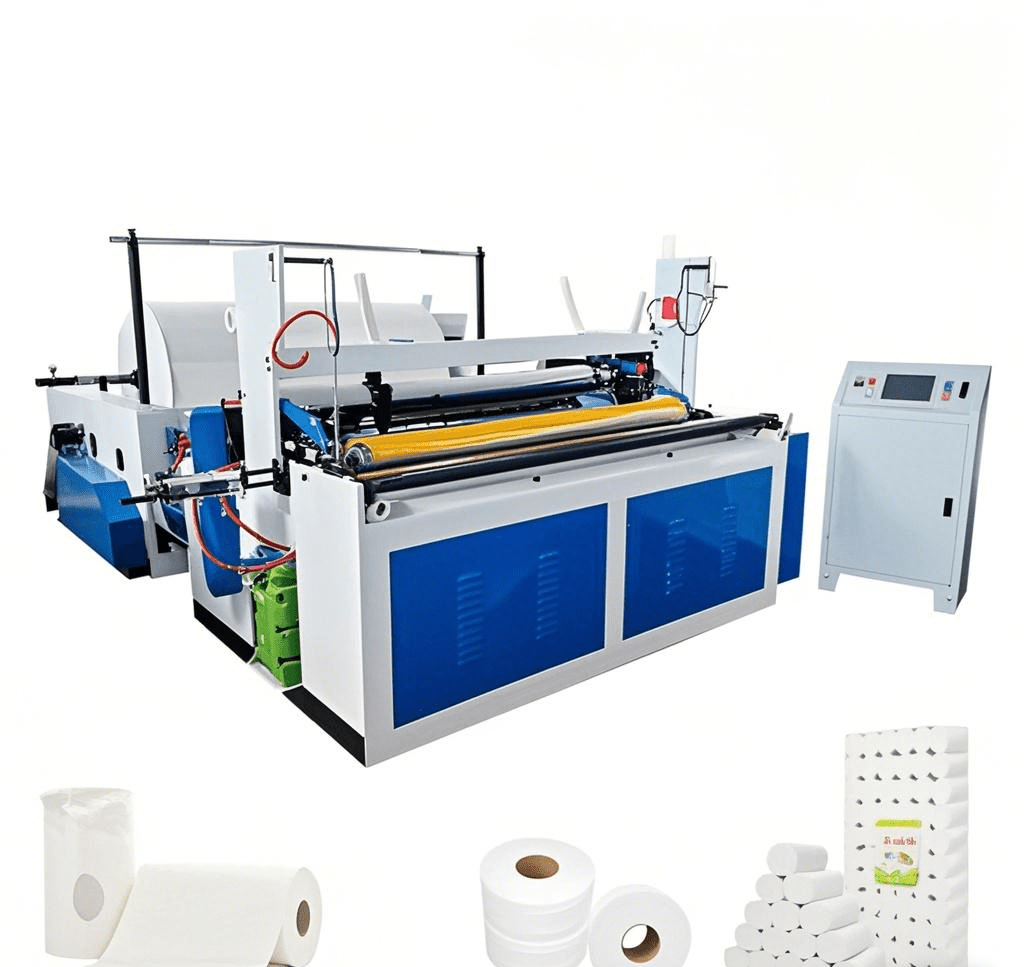

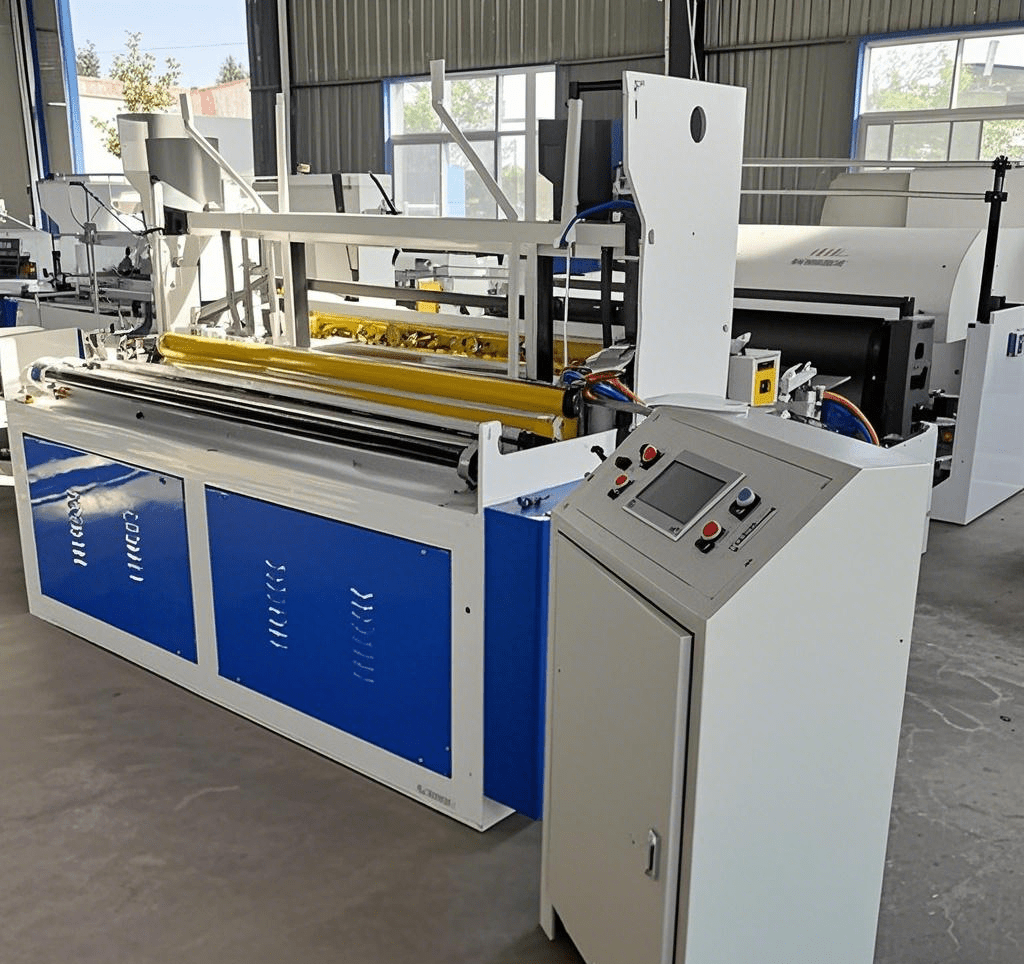

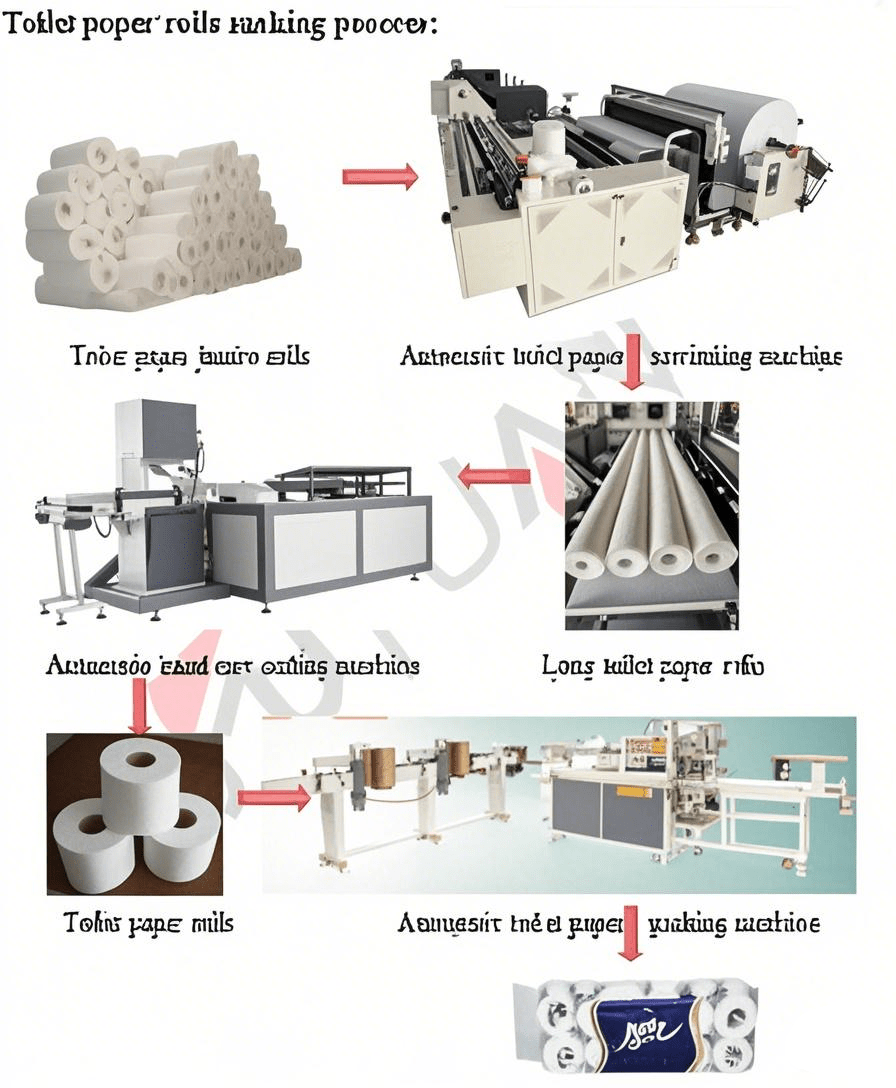

Automatic toilet paper roll processing equipment Toilet Paper Making Machine with Tissue Production Line High Efficiency

Automatic toilet paper roll processing equipment Toilet Paper Making Machine with Tissue Production Line High Efficiency

Couldn't load pickup availability

|

Model |

TD-1575 |

|

Finish products |

Toilet rolls |

|

Raw paper weight |

12-40 g/m2 tissue roll |

|

Raw paper width |

Max 1800mm |

|

Raw paper diameter |

1200 mm |

|

Finished diameter |

50-180mm |

|

Finished paper core |

Diameter 30-55mm |

|

Jumbo roll paper core |

Diameter 76mm |

|

Parameter setting |

PLC computer operating interface,touch screen |

|

Back paper stand |

2 layers synchronous transmission |

|

Perforation pitch |

80-220mm,150-300mm |

|

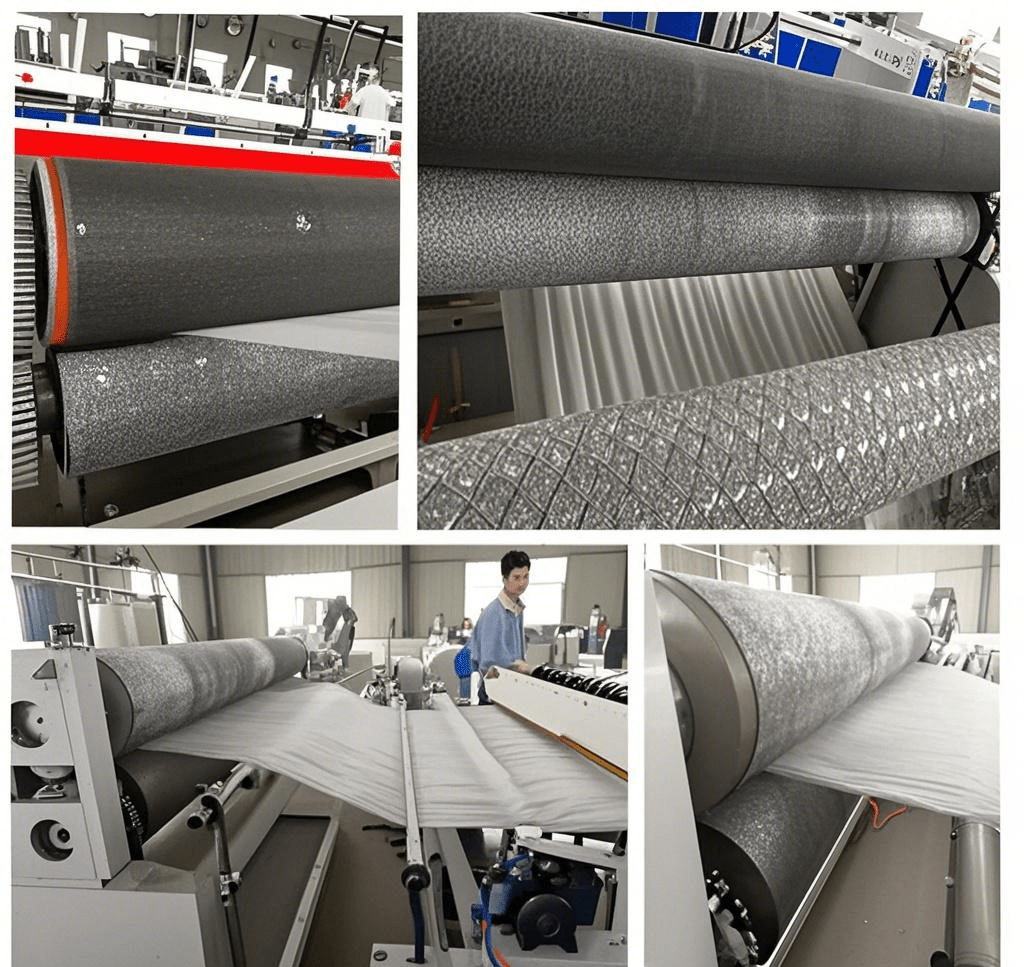

Embossing |

Steel roll to wool roll |

|

Perfuming device(optional) |

Automatic |

|

Paper loader |

Automatic Pneumatic loading paper rolls |

|

Paper core feeder |

Automatic paper core dropping system |

|

Glue Spraying,cutting rewinding, perforating |

Automatic

|

|

Total Power |

4 kw |

|

Production speed |

150-280 m/min |

|

Voltage |

3 Phase 380V,50HZ |

|

Air pressure |

0.5 Mpa |

|

Dimensions |

6500*3400*1800 mm |

|

Weight |

2500 kg |

|

Qty |

1 set |

|

Spare parts |

Perforation knife 2pcs Round blade 1pcs |

|

Model |

TD-BSP01 |

|

Applicable scope |

Facial paper,toilet paper |

|

Cut length |

Adjustable length |

|

Finish size |

adjustable |

|

Working speed |

50-100 cut/min |

|

Control system |

PLC control,servo drive, touch screen operation |

|

Cutting swing structure |

Cam structure |

|

Compressed air |

0.5-0.6 Mpa |

|

Power needed |

3 phase 380V,50HZ |

|

Weight |

1200 kg |

|

Model |

TD-JZ |

|

Product name |

Automatic toilet paper packing machine |

|

Capacity |

15-20 bags/minute |

|

Compressed air |

0.6 Mpa |

|

Power needed |

3 phase 380V,50HZ |

|

Power |

2 kw |

|

Size |

5*1*1.5m |

|

Weight |

1000 kg |

Share