what is SGJ-80 capping machine

Share

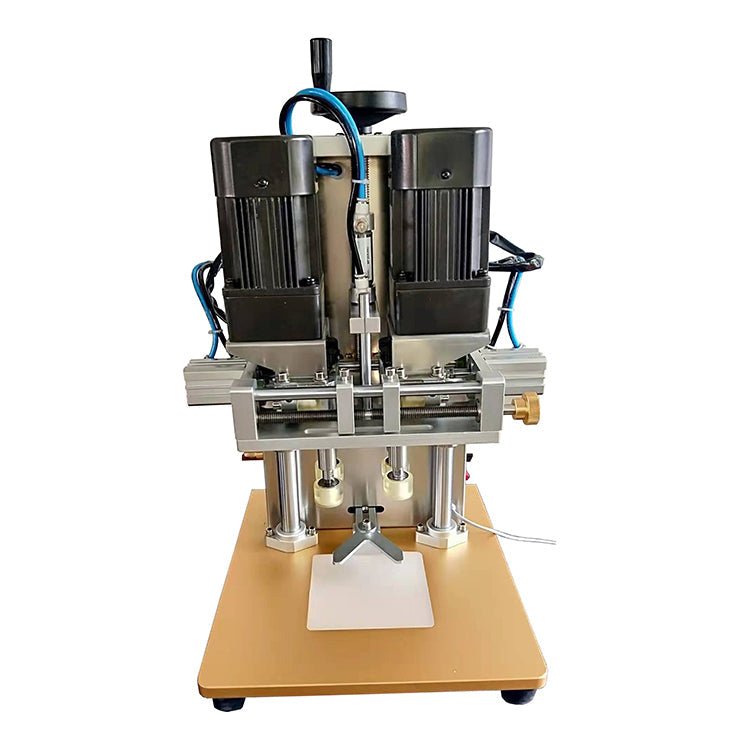

The duckbill cap torque machine is an automated device used for tightening various types of bottle caps, primarily utilized in the production lines of food, beverage, pharmaceutical, and other industries. Here is a detailed introduction to the duckbill cap torque machine:

-

Working Principle

- The duckbill cap torque machine operates through electronic control of movement, allowing for free adjustment of capping speed.

- It is equipped with positioning devices to ensure ease of operation and high production efficiency.

- Capable of handling a wide range of cap diameters, it can accommodate different specifications of bottle caps.

-

Technical Parameters

- Applicable bottle types include both glass and plastic bottles.

- Suitable for bottle cap diameters ranging from Φ30-80mm, with a production capacity of 1000-1800 bottles per hour.

- Power supply: AC220V 50/60Hz; weight approximately 150KG.

-

Product Features

- Rationally designed, with cylinder control ensuring stable bottle operation during the capping process.

- The capping head is fitted with TPR rubber wheels to minimize damage to the caps.

- Variable frequency speed control is used for bottle feeding and capping, ensuring stable conveyor and capping speeds.

- The entire machine is made of 304 stainless steel, complying with GMP standards.

-

Application Areas

- Widely used in the food, beverage, pharmaceutical, pesticide, chemical, and other industries.

- Suitable for various types of bottle caps such as duckbill caps, threaded caps, spray caps, and tamper-evident caps.

In summary, the duckbill cap torque machine is an efficient and stable automated sealing device that meets the cap-tightening needs of various industries. Its extensive application areas and advanced technical parameters make it an indispensable part of modern production lines.