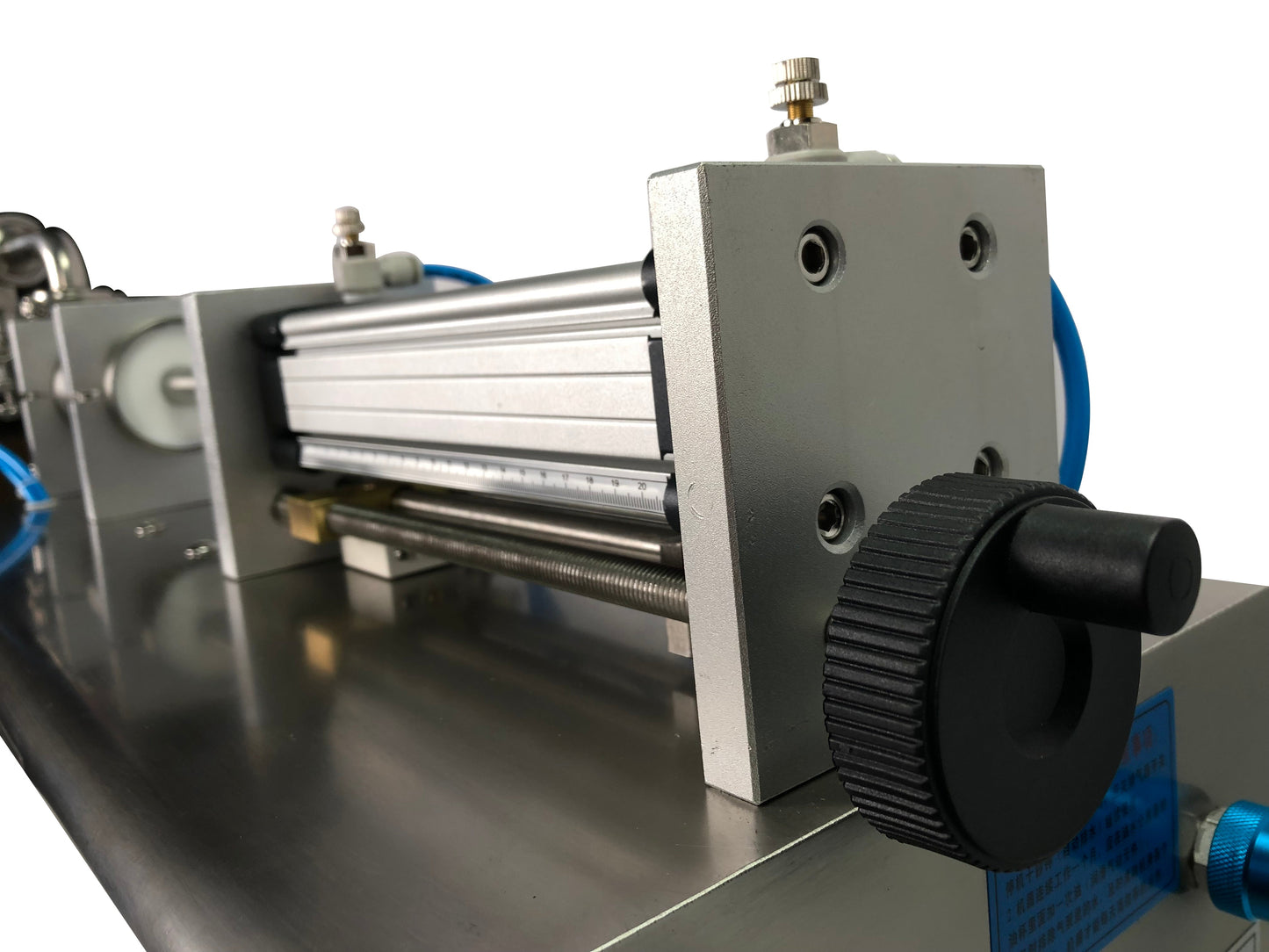

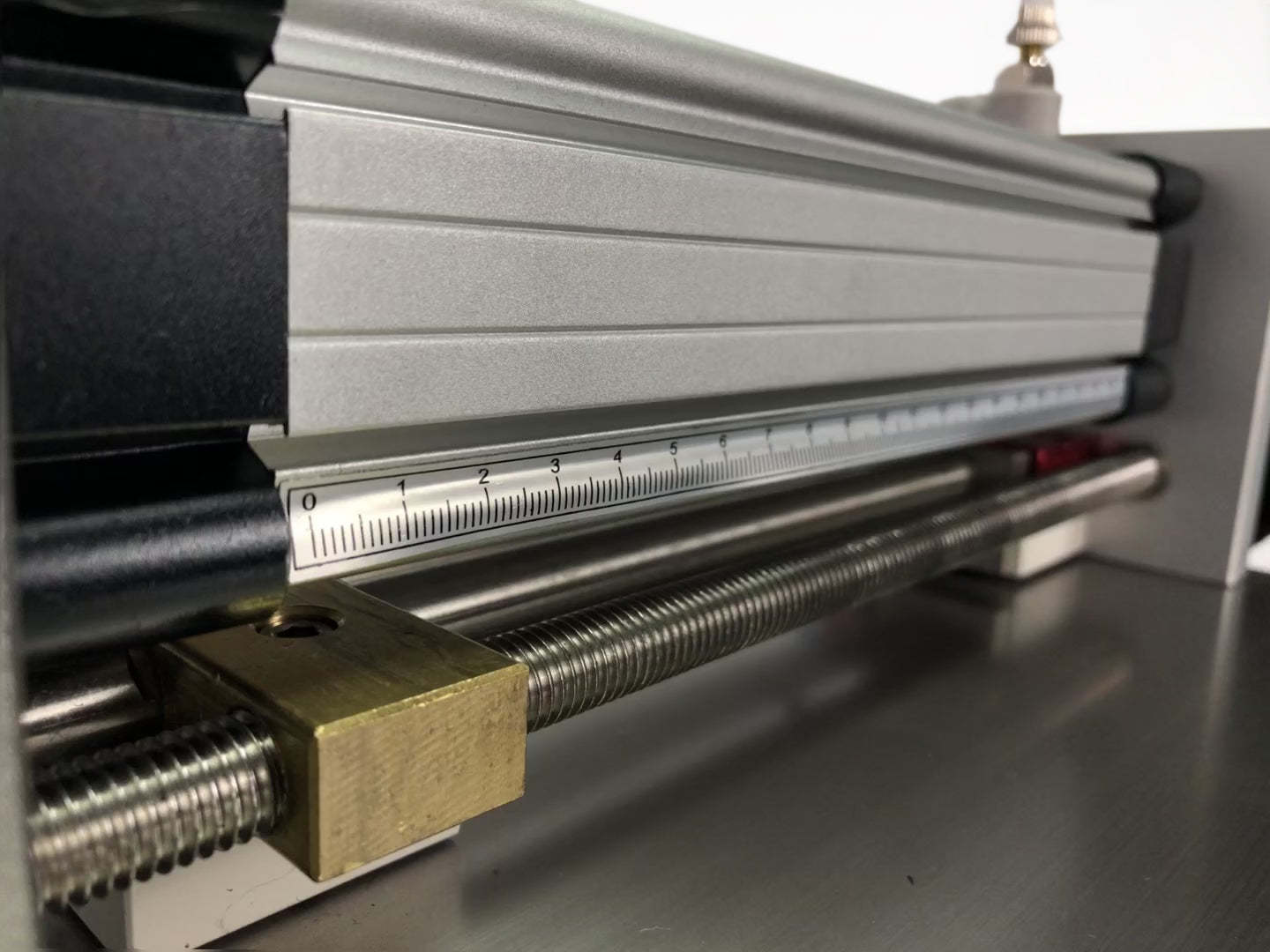

CECLE packaging machinery

semi automatic one nozzle paste gel and hand sanitizer filling machine O-rings, sealing rings

semi automatic one nozzle paste gel and hand sanitizer filling machine O-rings, sealing rings

Couldn't load pickup availability

Semi automatic one nozzle paste gel and hand sanitizer filling machine O-rings

Free shipping by express ( Delivery time 5~15 days)

Preparing time is about 3-7 days

| Model | O-rings |

| Compression Ratio | 10%-30% compression ratio |

| Working Temperature | -20°C to 200°C |

| Ring Cross Section | O-ring, U-ring, V-ring etc., |

| Radial Dimensional Tolerance | CONTROLLED or NORMAL grade acceptable |

| Surface Roughness | Precisely machined Ra 0.4~0.8μm surface. |

| Durability | withstand up to 1 million sealing cycles |

| Anti-corrosion Treatment | Like fluorination to increase service life. |

The main advantages of using sealing rings for filling machines are:

1. Good sealing effect - Reliably prevent liquid and gas leaks.

2. Easy to use - Simple and quick installation and removal.

3. Low sealing pressure - Reduces mechanical wear and energy consumption.

4. Wide sealing range - Can be used for static and dynamic sealing.

5. Long seal life - Well-made seals can be reused.

6. Low cost - Lower use and maintenance costs compared to mechanical seals.

7. Self-healing - Seals can self-repair seals when surfaces are damaged.

8. Corrosion resistance - Corrosion resistant materials can be chosen.

9. High temperature resistance - Special materials can withstand up to 300°C.

10. Shock absorption - Absorbs impacts and vibrations to protect sealing surfaces.

In summary, using seals can simplify design, improve sealing performance of filling machines, and prolong service life.

Share