An Introduction to Horizontal Cartoning Machines for Automatic Toothpaste Packaging

Share

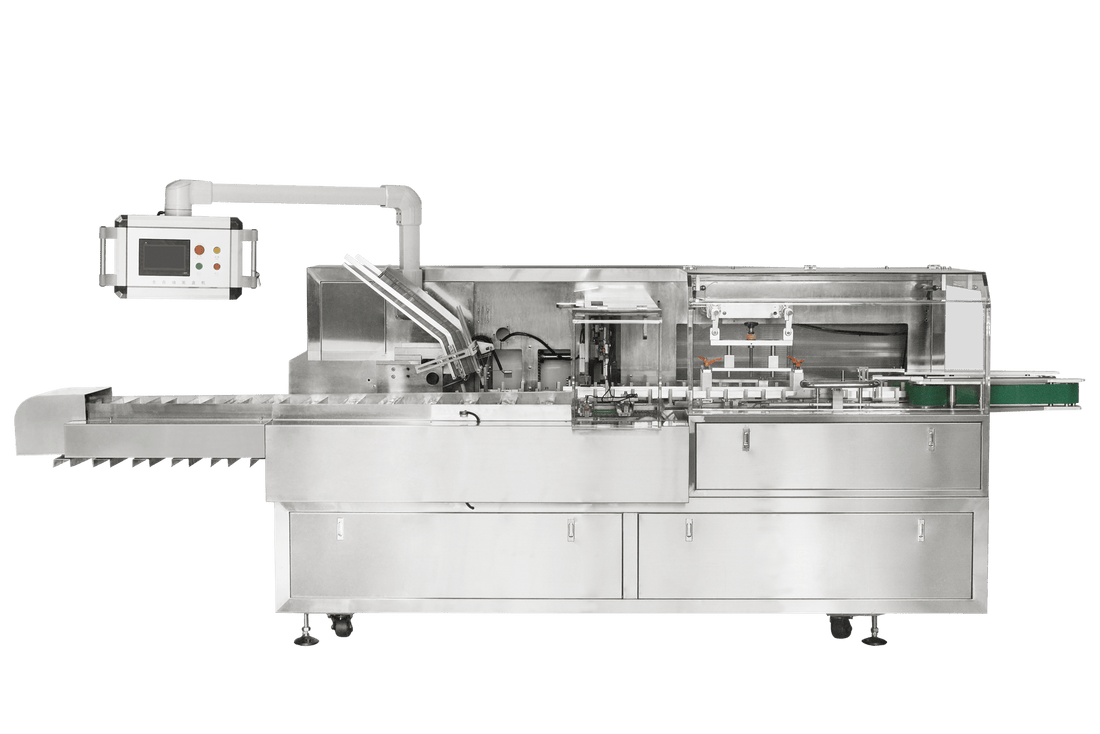

In the fast-moving consumer goods (FMCG) industry, efficiency and reliability in packaging are paramount. For products like toothpaste tubes, horizontal cartoning machines are the engineered backbone of the packaging line, seamlessly transforming loose tubes into beautifully boxed, retail-ready products. This article outlines the sophisticated process of how a horizontal cartoning machine automatically packages toothpaste.

What is a Horizontal Cartoning Machine?

A horizontal cartoning machine is a type of automated equipment designed to insert products into cartons that are loaded horizontally. Unlike vertical machines that drop products in from above, horizontal machines are ideal for products like toothpaste tubes that are best inserted lengthwise into a pre-glued carton. They are celebrated for their high speed, flexibility, and robust performance.

The Step-by-Step Automatic Packaging Process

The journey of a toothpaste tube from a loose item to a packaged good involves several meticulously coordinated steps:

1. Carton Erection:

-

The process begins with a stack of flat, pre-cut, and creased carton blanks being loaded into the magazine of the machine.

-

A suction cup precisely picks up a single blank and unfolds it, forming a rectangular sleeve with pre-applied glue on one flap or a interlocked closure ready for sealing.

2. Tube Feeding and Orientation:

-

Simultaneously, toothpaste tubes are fed into the machine's infeed lane via a conveyor belt or vibratory feeder.

-

Optional vision systems or guides ensure each tube is correctly oriented (e.g., cap-first) before entering the loading station.

3. Product Insertion:

-

This is the core of the operation. The opened carton is transported horizontally to the loading station.

-

At the precise moment, a mechanical pusher arm or a set of belts gently but firmly inserts the toothpaste tube completely into the waiting carton. This horizontal loading method is gentle on the product and prevents damage to the tube or its cap.

4. Optional Insert Placement (e.g., Instructions):

-

Many toothpaste boxes include an information leaflet or a small insert. This machine can be equipped with an auxiliary module that picks and places these inserts into the carton alongside the tube before the final closure.

5. Carton Closing and Sealing:

-

Once the tube (and any insert) is loaded, the carton moves to the closing section.

-

The remaining flaps are neatly folded down. For pre-glued cartons, the closure is secured through heat or pressure. For tuck-style closures, mechanical fingers precisely tuck the flap into the box.

-

This creates a perfectly sealed and presentable package, ready for shipping and store shelves.